Today, membrane industry is one of the novel and growing industries in the field of gas separation. Gas separation is used in different sectors of oil industry, petrochemical industry, and gas industry.

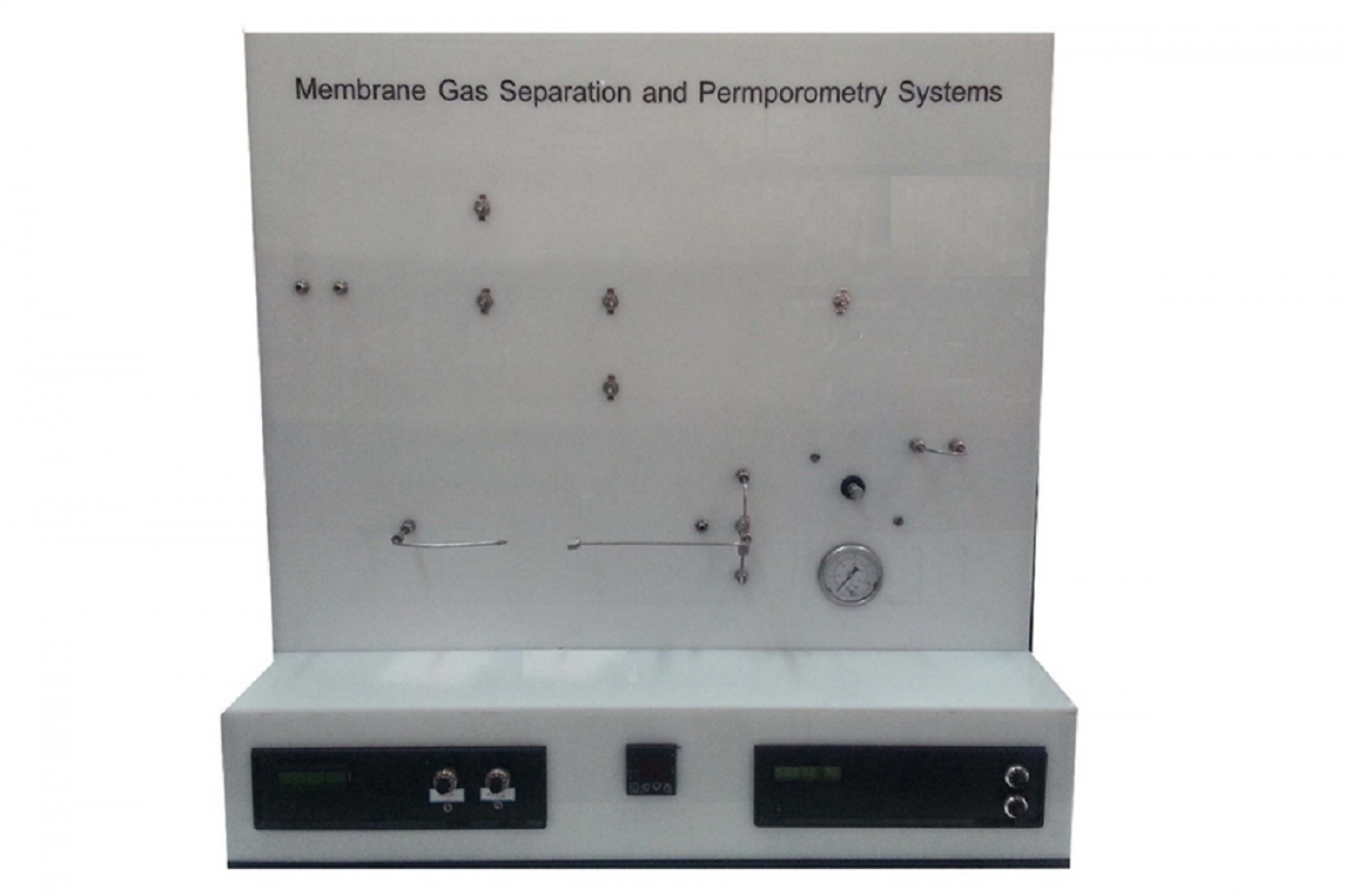

Today, membrane industry is one of the novel and growing industries in the field of gas separation. Gas separation is used in different sectors of oil industry, petrochemical industry, and gas industry. Thus, development of methods to evaluate produced membranes can be of great importance. These devices should be adaptable with different gas analysis tools like gas chromatography.

The general mechanism of these devices is simple but very practical. In these devices, gases are usually miscible with MFCs. First, the membrane is placed in the device, and then a certain percentage of gases are mixed and conducted towards the membrane with a specified pressure and flow rate. It is clear that a portion of gas mixture passes through the membrane and the other part does not pass through; these two output streams are called Permeate and Retentate, respectively. To determine the output streams compositions, the device outputs are fed into a secondary analysis device. The secondary analysis instrument can be gas chromatography or another analysis tool. By determination of the feed gas and output streams percentages, the ability of membrane in gas separation is determined.

These devices also have Permporometry capability. In this case, by merging two inert gas streams, which one of them passes through a saturator, a certain percentage of the solvent about 2% (equivalent to the values of pores below 2 nm) passes through the membrane. To change and increase the partial pressure of the solvent, it is enough to change the ratio of these two streams (equivalent to the larger pores values). The permeate stream velocity is a function of solvent partial pressure and by using the Kelvin equation, the pore size distribution of the membrane surface is obtained.