Mixer mill has been developed for grinding of brittle and hard materials or soft and fiber materials down to micro and nano scales.

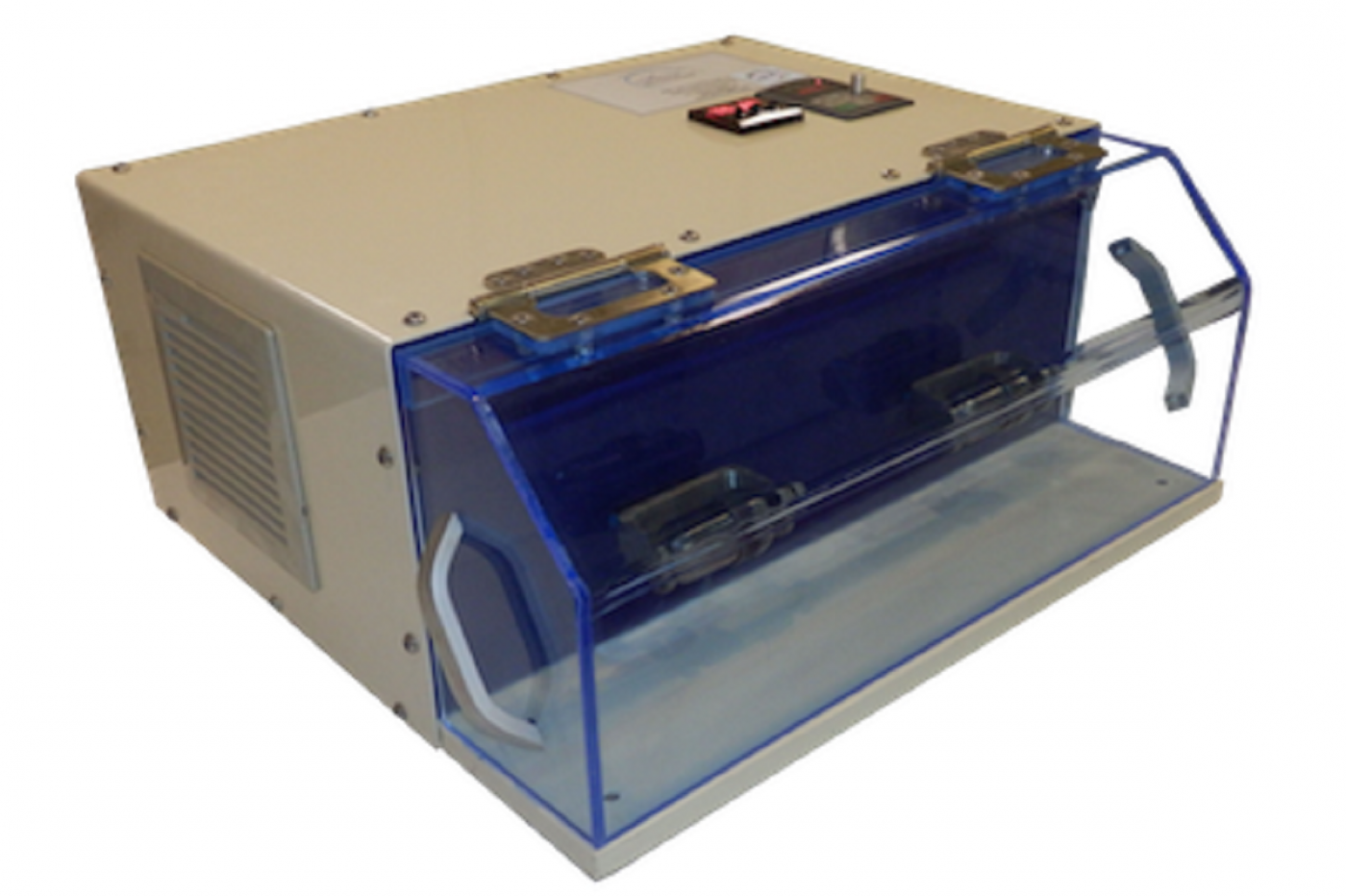

Mixer mill has been developed for grinding of brittle and hard materials or soft and fiber materials down to micro and nano scales. The device operation principle is the oscillations of the grinding jars in a horizontal position which combines with the movement of the grinding balls inside the jars. These types of movements cause the collision between balls and sample material and consequently size reduction. Compared to other types of grinding mills, the mixer mill due to the specific movements of the grinding jars and high speed oscillation (up to 50 cycle per second) reduces the grinding time. One of the unique features of the mixer mill is the ability of grinding biological materials in genetic laboratories; generally during grinding process, the biological materials due to their soft structures agglomerate, or their tissue breaks down and their properties change. Therefore, grinding of these types of materials is difficult. To obviate these challenges and difficulties, Amin Asia Company has designed a mixer mill with ability of grinding at low temperature (cryogenic grinding mode) which facilitates the grinding of soft and heat-sensitive materials.