Physical Vapor Deposition (PVD) is the name of large family of vacuum-based layer deposition methods which today is being extensively used for production of thin films and coatings.

Introduction

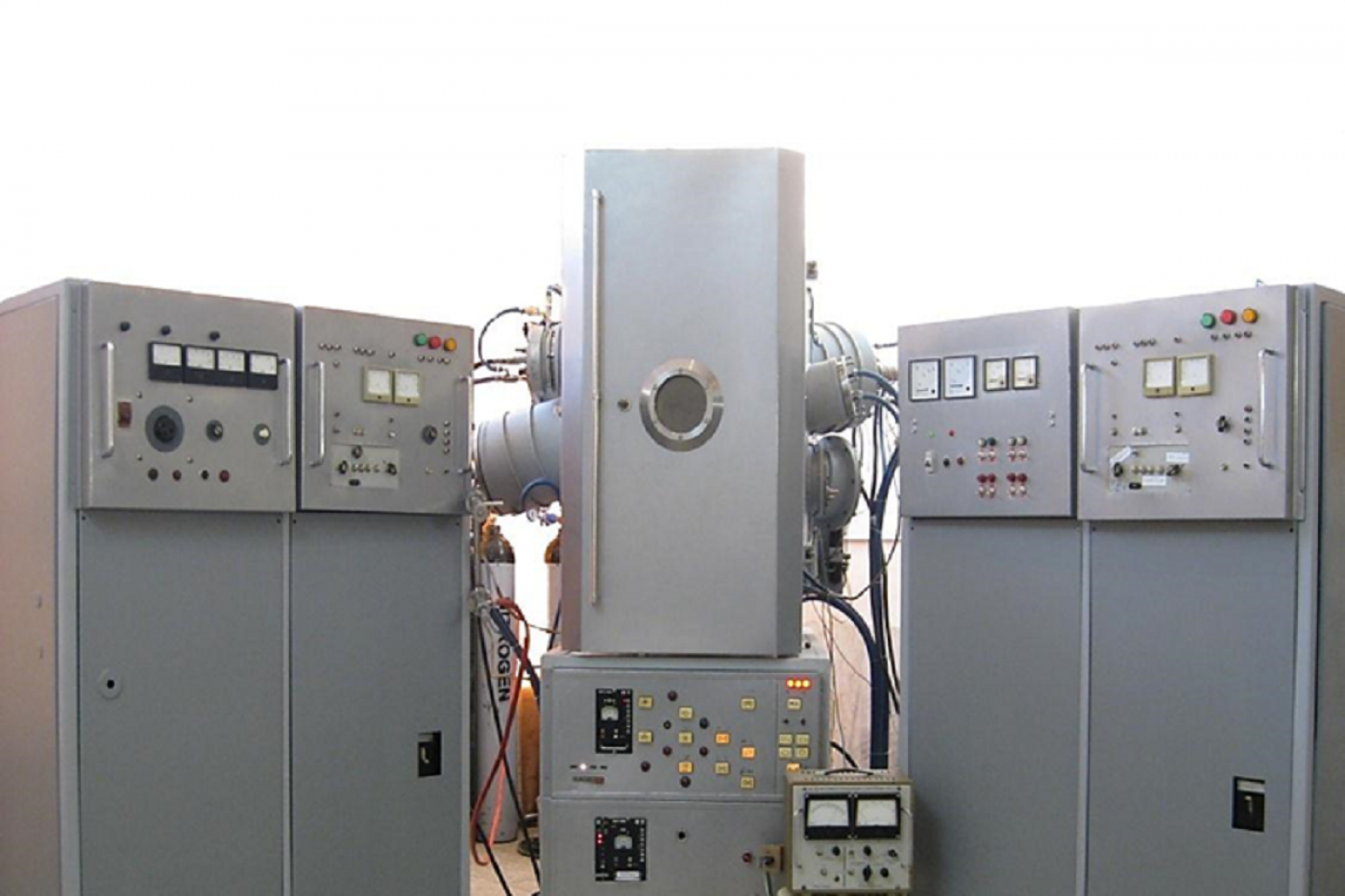

Physical Vapor Deposition (PVD) is the name of large family of vacuum-based layer deposition methods which today is being extensively used for production of thin films and coatings. In all PVD methods, the material goes from a condensed phase (usually named Target) to a vapor phase and then condenses and deposits in a form of thin film onto the desired substrate.

The most common PVD processes are sputtering and evaporation. In sputtering method, there is much more focus on the ion bombardment of the Target which is basically non-thermal route, while in the other methods like resistive heating, electron-beam heating and cathodic arc, the use of a thermal source is responsible for vaporization of solid Target to the gas fume.

In the Cathodic arc deposition (also called Arc-PVD) an electric arc is used to vaporize material from a cathode target. In the deposition process, elements, alloys, or compounds are vaporized and deposited in a vacuum. The process is carried out at pressures below 0.1 Pa (1 mTorr) and usually in a vacuum ranging from 10 to 0.1 mPa. The substrate temperature may vary from room temperature to 500 °C.

The vaporized material then condenses onto a substrate and forms a thin film. The technique can be used to deposit metallic, ceramic, and composite films. Industrial application of modern cathodic arc deposition technology began in 1960s to 1970s. The arc evaporation process begins with the striking of a high current, low voltage arc on the surface of Target which leads to a small but highly energetic emitting area known as a cathode spot. The temperature in the cathode spot rises locally up to 15000 °C, which results in a high velocity fume of vaporized cathode material. The cathode spot is only active for a short period of time and then it becomes inactive and re-ignites in a new area close to the previous crater. This behavior causes the apparent motion of the arc.

The advantage of vacuum evaporation is that films of a variety of materials can be deposited at high rates over large areas in a very pure form. Because this deposition process is a kind of so-called line-of-sight, deposition on a rough or nonplanar surface may be problematic, and may result in non-uniformity in film thickness and variability in film morphology. Cathodic arc deposition is vastly used to synthesize extremely hard films to protect the surface of cutting tools and extend their life. A wide variety of hard thin films, Super hard coatings and nanocomposite coatings can be synthesized by using this technology including TiN, TiAlN, CrN, ZrN, AlCrTiN and TiAlSiN.

Application

- Deposition of hard thin films, super hard coatings and nanocomposite coatings, including TiN, TiAlN, CrN, ZrN, AlCrTiN and TiAlSiN

specification

Details of technical specifications are presented in the following Table.

Advantager of using nanotechnology

Advantager of using nanotechnology

A wide variety of hard thin films (even below 100 nm), Super hard coatings and nanocomposite coatings can be synthesized by cathodic Arc-PVD including TiN, TiAlN, CrN, ZrN, AlCrTiN and TiAlSiN