Electrospinning is a unique method to produce ultrafine fibers (micrometer to nanometer) with high specific surface area from polymer solutions or melts using electrical energy. Typically, electrospinning needs a direct current (DC) in the range of several tens of kV. Currently, electrospinning device has two standards, i.e. vertical and horizontal. This process is carried out at room temperature and at normal pressure. Most of the polymers are dissolved in a suitable solvent before electrospinning process.

Introduction

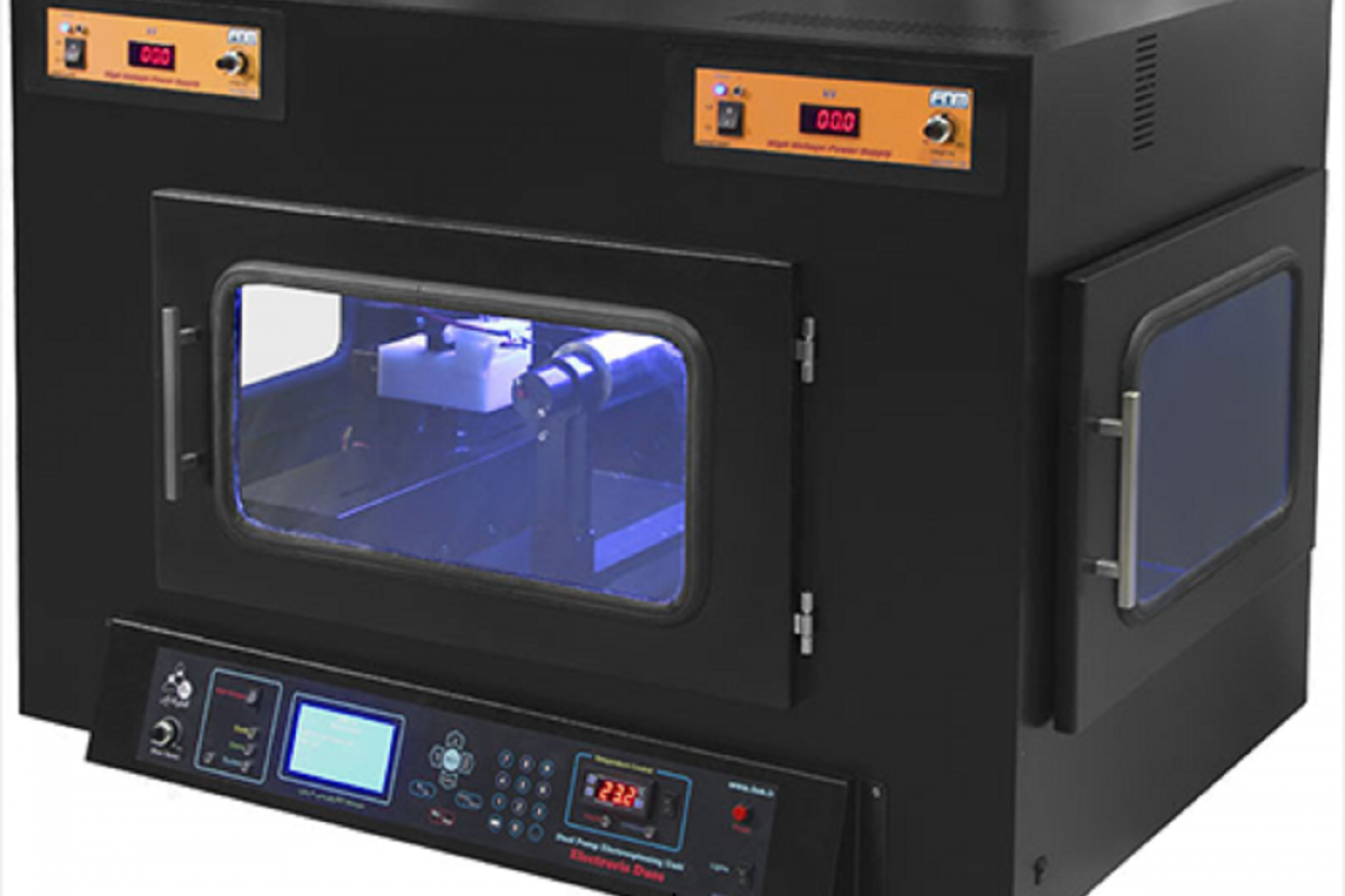

Electrospinning is a unique method to produce ultrafine fibers (micrometer to nanometer) with high specific surface area from polymer solutions or melts using electrical energy. Typically, electrospinning needs a direct current (DC) in the range of several tens of kV. Currently, electrospinning device has two standards, i.e. vertical and horizontal. This process is carried out at room temperature and at normal pressure. Most of the polymers are dissolved in a suitable solvent before electrospinning process. An electrospinning system consists of three main parts including a high voltage power supply, a spinneret and a ground plate collector. The power supply applies a specific polarity to a polymer solution or melt, the solution is then accelerated towards a collector with opposite polarity. The polymer solution is introduced into a capillary tube and held there by its surface tension force. By applying electric current to the liquid surface via the capillary tube, the electric forces overcome the surface tension forces and lead to the formation of a jet of the solution which exits from the end of the tube. When solution ejects from the Taylor cone tip, due to the instability and high speed that occur in the space between the capillary tip and the collector, the solution jet with a millimeter diameter turns into one or several jets with a diameter in the nanometer range; finally the solvent evaporates and the fibers remain.

Application

Designed to produce polymer/ceramic nanofibers in large quantities.

specification

The dip electrospinning units provided by this company are designed and produced in three different models. Details of technical specifications are presented in the following Table.

Advantager of using nanotechnology

Advantager of using nanotechnology

When the repulsive electrostatic forces overcome the surface tension forces, the destruction, bending, twisting and stretching of fibers occur with respect to the device conditions; occurrence of a combination of these phenomena or each one individually can lead to the conversion of a solution jet with millimeter diameter to one or several jets with a diameter in the nanometer range. So this device can be mainly utilized in production of nanofibers.

Manual and maintenance

- Device must be used by a fully trained person.

- When drum is in contact with chemicals, use special gloves to remove it from the device.

- Be careful when mounting the tub at the desired place and avoid applying pressure to the gear and damaging it.

- For more details on how to use the device, refer to the device catalog and user guide.

Safety and package

- Inappropriate use of the device high voltage power supply can cause electric shock or death.

- Check all connections, especially the system earth connection cable, and make sure they are correct.

- Avoid opening the device door when the high voltage power supply is on; and only connect the high voltage cable to the tub and collector.

- During device operation, make sure that the device door is closed, or use safety glasses to protect your face against the splashing of polymer solution or melt

Product basket

| Product Title |

Certification Code |

Expire Date |

| NL20 Model |

94102 |

2020/02/20 |

| NL50 Model |

94102 |

2020/02/20 |

| NL100 Model |

94102 |

2020/02/20 |