Chemical Vapor Deposition (CVD) is a process in which the gas precursors, activated by heat, light or plasma in a chamber, react on or near the vicinity of a heated substrate surface and deposit in a solid phase onto the surface.

Introduction

Chemical Vapor Deposition (CVD) is a process in which the gas precursors, activated by heat, light or plasma in a chamber, react on or near the vicinity of a heated substrate surface and deposit in a solid phase onto the surface. CVD is one of the deposition methods which can be used for fabrication of metallic, non-metallic, carbides, nitrides, oxides and intermetallics coatings. Plasma Assisted Chemical Vapour Deposition (PACVD) is one of the CVD methods which attracted special attention in deposition process of the industrial components and tools. The presence of energetic particles (ions, electrons, etc.) and continuous bombardment of the metallic surface by these particles makes a suitable condition for occurrence of chemical reactions and creation of coatings at low temperatures. Moreover, surface bombardment by energetic particles removes the surface oxide layers and as a result modifies the physical, chemical and mechanical properties of the coating. Thus, in comparison with the common CVD process, in PACVD the chemical reactions, which lead to the formation of coating, happen at lower temperatures.

In this process, the samples are first subjected to a surface cleaning in an inert gas plasma medium like argon and their temperature increases to the desired value. Then gaseous reactants, a mixture of nitrogen, hydrogen, argon and TiCl4 gases with certain ratios, are sent into the chamber; finally the deposition process is performed by controlling parameters such as temperature, time, pressure, frequency and pulse width. Using this method makes it possible to fabricate single- or multilayers binary, ternary and quaternary coatings such as TiN, TiC, CNTi, TiAlN, TiBN and TiAlCN. One of the advantages of this method is the ability to perform nitration process and consequently deposition process, which leads to the formation of hard coatings. What’s more, this method has a higher deposition rate compared with the other methods, while maintaining the deposition quality.

Application

Some applications of PACVD are as follows:

- Improving corrosion resistance of components

- Coatings for plastic molds, aluminum and sensitive components in the automotive and aerospace industries

- The growth of carbon nanotubes onto different sensors and electronic and optical components

specification

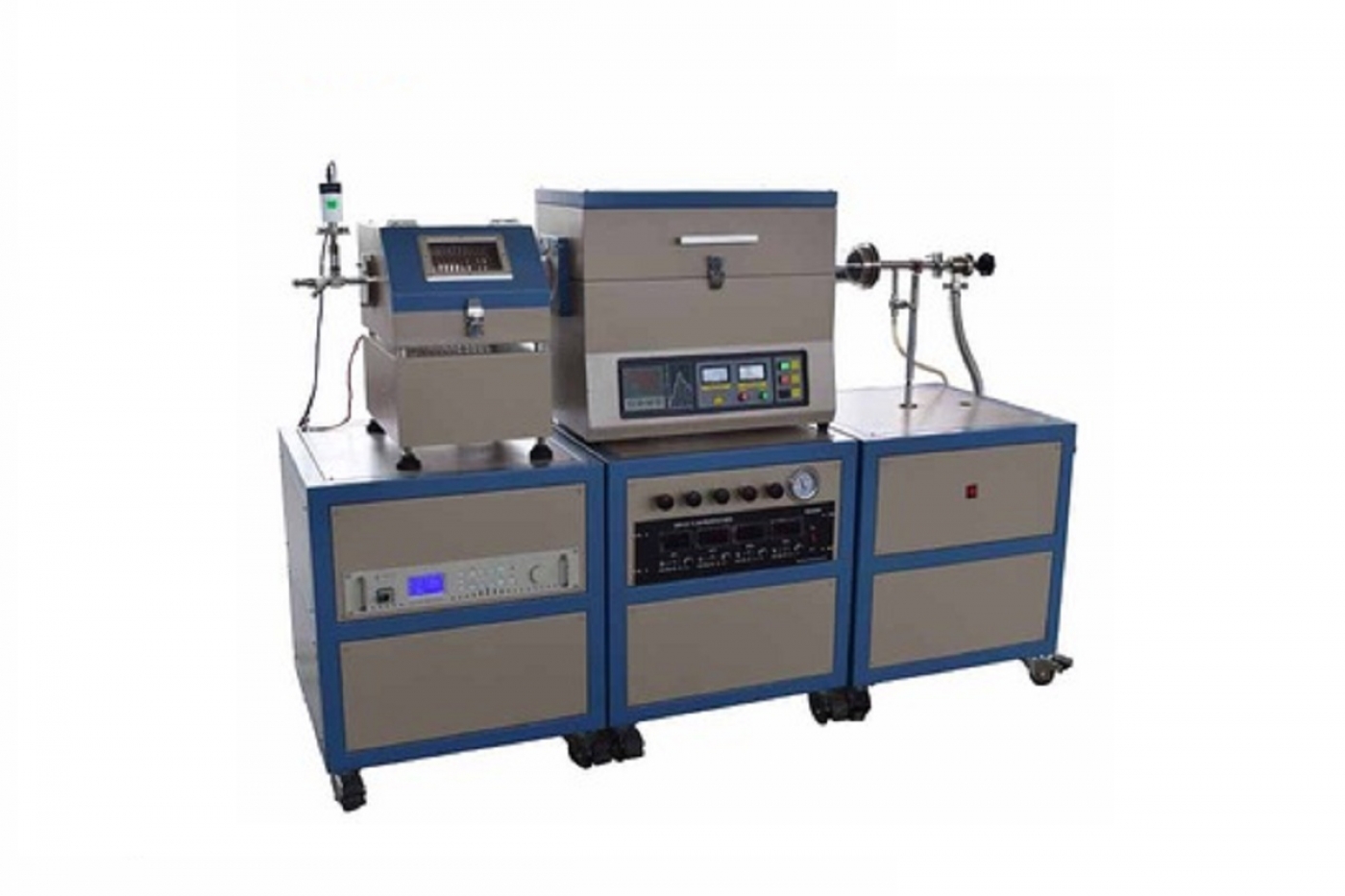

The PECVD systems provided by this company are designed and produced in three different models. Details of technical specifications are presented in the following Table.

Advantager of using nanotechnology

Advantager of using nanotechnology

Today, chemical vapor deposition is a unique technique in production of some nanomaterials. Production of various allotropes of carbon such as carbon nanofibers, carbon nanotubes, nanodiamond and graphene can be mentioned as examples. However, of the particular applications of PACVD in the field of nanotechnology, fabrication of metallic and non-metallic single- or multi-layers with different compounds, as well as the possibility of the growth of carbon nanotubes onto a variety of electronic and optical components can be mentioned.

Manual and maintenance

- To begin the operation, first open the chamber door and clean its interior from any contamination, including oxides, filings, dust and residues from previous process; otherwise the deposition process fail to perform properly and the deposited layer contaminates.

- Remove any types of contaminants from the samples surfaces, and then put them on the platform with appropriate distances from each other, and close to the nozzle.

- To use gases, first open the capsules valve and then adjust the output pressure through the outlet pressure regulator at 3 bar.

- Before using the plasma, chamber must be heated by employing an external heater. To do this, set the desired temperature via the controller (for example, 500 °C) and then press the heater switch. By doing this, the heater turn on automatically and raise the chamber temperature.

- For plasma generation, the pressure of the chamber must be low at first.

- During the process the temperature should be constant; this is done by using the external heating system and the heat generated by the plasma.

- By finishing the deposition process, plasma automatically cuts off. Therefore, to prevent chemicals from remaining in the reaction chamber, it is necessary to close the inlet and outlet valves of the chemical tank a few minutes before finishing the deposition process.

- After cooling, to remove the samples from the chamber, the chamber vacuum must be broken at first.

- After ensuring that the vacuum is completely broken, open the chamber door and remove the samples carefully.

- For more details on how to use the device, refer to the device catalog and user guide.

Safety and package

- Before starting the operation, use safety equipment such as a mask and gloves to clean the chamber.