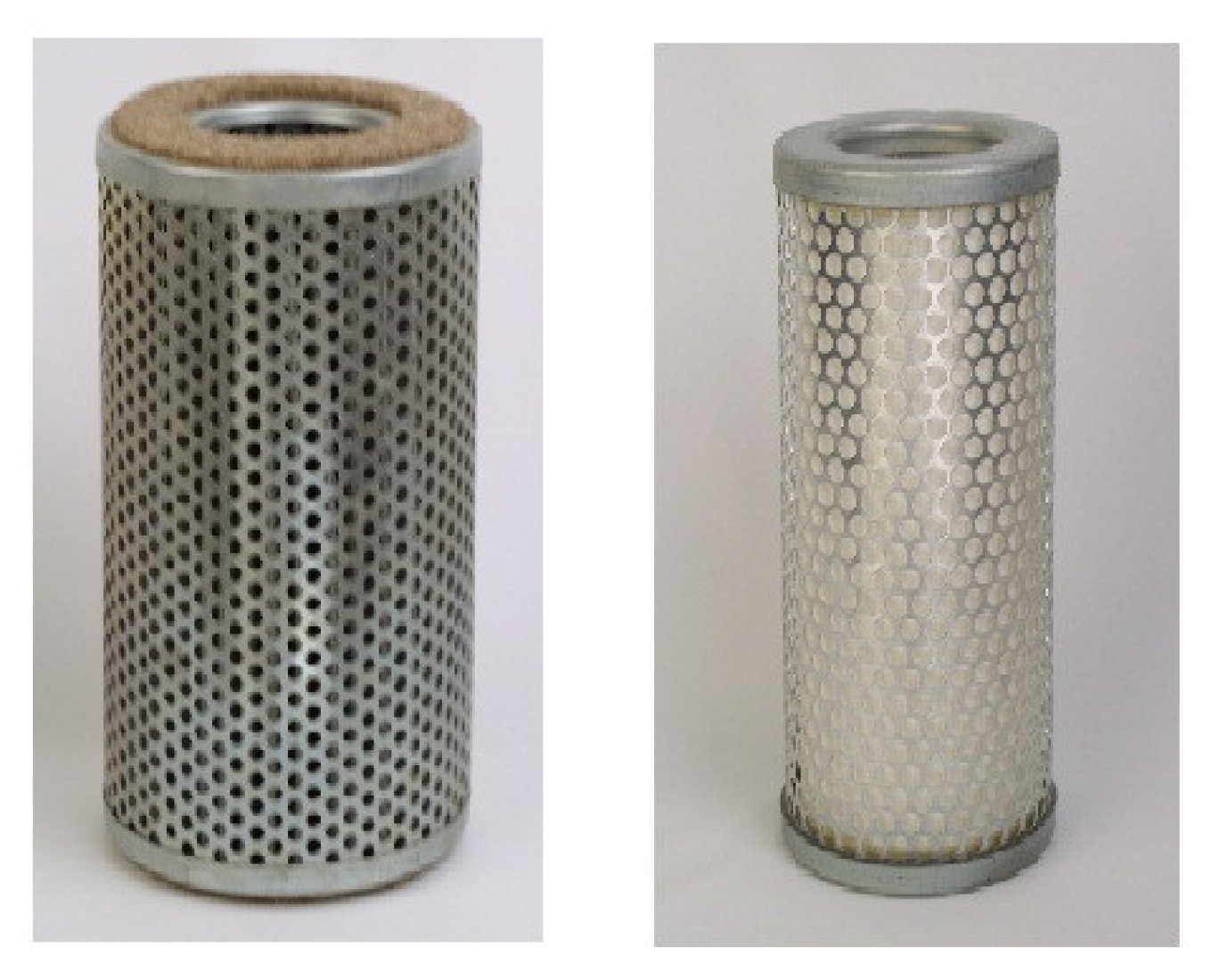

Filtration is a mechanical or physical process that is used in various industries such as cement and gypsum production, petrochemicals, natural gas transmission and in compressors. During this process, solid suspended metariels are separated from fluids such as air, water, gas or oil. These particles when passing through the filter, adhere to the constituent fibers and will not pass through the filter. Therefore, the smaller pores in the filter increase the efficiency of the filter and can prevent the passage of smaller particles. However, increasing the fiber density of the filter bed increases the pressure drop and thus increases energy consumption. The use of filters with nanofiber coating due to high surface area, length to width ratio and low density increases the efficiency of the filter in absorbing finer particles without a significant increase in pressure drop of the filter compared to the filter without nanofibers. This increases the quality of the passing fluid and as a result increases the life of the parts and reduces the repair and stopping time. The mechanism of action is that a thin layer of nanofiber mesh is a barrier to particles; while the gas is passed through a large volume through small holes. The electrospun fibers are less than 100 nm in diameter and cover the surface of the filter paper evenly. These nanofibers are usually made of polyamide.

Dry Gas Filter is one of the most common filters used in the gas industry and is the last stage of filtration in the gas supply system and can be installed and used in two types, vertical and horizontal. Natural gas, after refining and leaving refineries and before being transferred to gas pressure reducing stations, contains solid particles and sediments, dirt and dust and even moisture. Dry gas filters are used to prevent these solid particles from damaging the regulators, valves and the equipment used in pressure reducing stations and gas supply lines.