Nano Zirconium

Coating of part surfaces have been usually done for enhancing the corrosion resistance of metallic components and equipment. Imposing conversional coatings is one the most cost-effective conventionally applied techniques that increase pigment adhesion to surface as well as increasing corrosion resistance. Phosphate and Chromate-based conversional coatings are two frequently-used types of such protective coatings. Taking remarks such as environmental concern, health care and process cost into consideration, attempts have been made to take the advantage of other alternative coatings like oxides of zirconium, titanium and vanadium instead of old phosphate and chromate-based ones. In contrary to phosphate and chromate-based coatings, zirconium-based ones are with no environmental hazard and process can be carried out at ambient temperature in a more reasonable time period. Having a relatively lower weight of these novel zirconium-based coatings is another superior property of them over the conventional phosphate/chromate-based materials. Furthermore, there is no need of sludge neutralization in deposition of zirconium-based coating in which a required process in exposing phosphate or chromate-based conversional coatings.

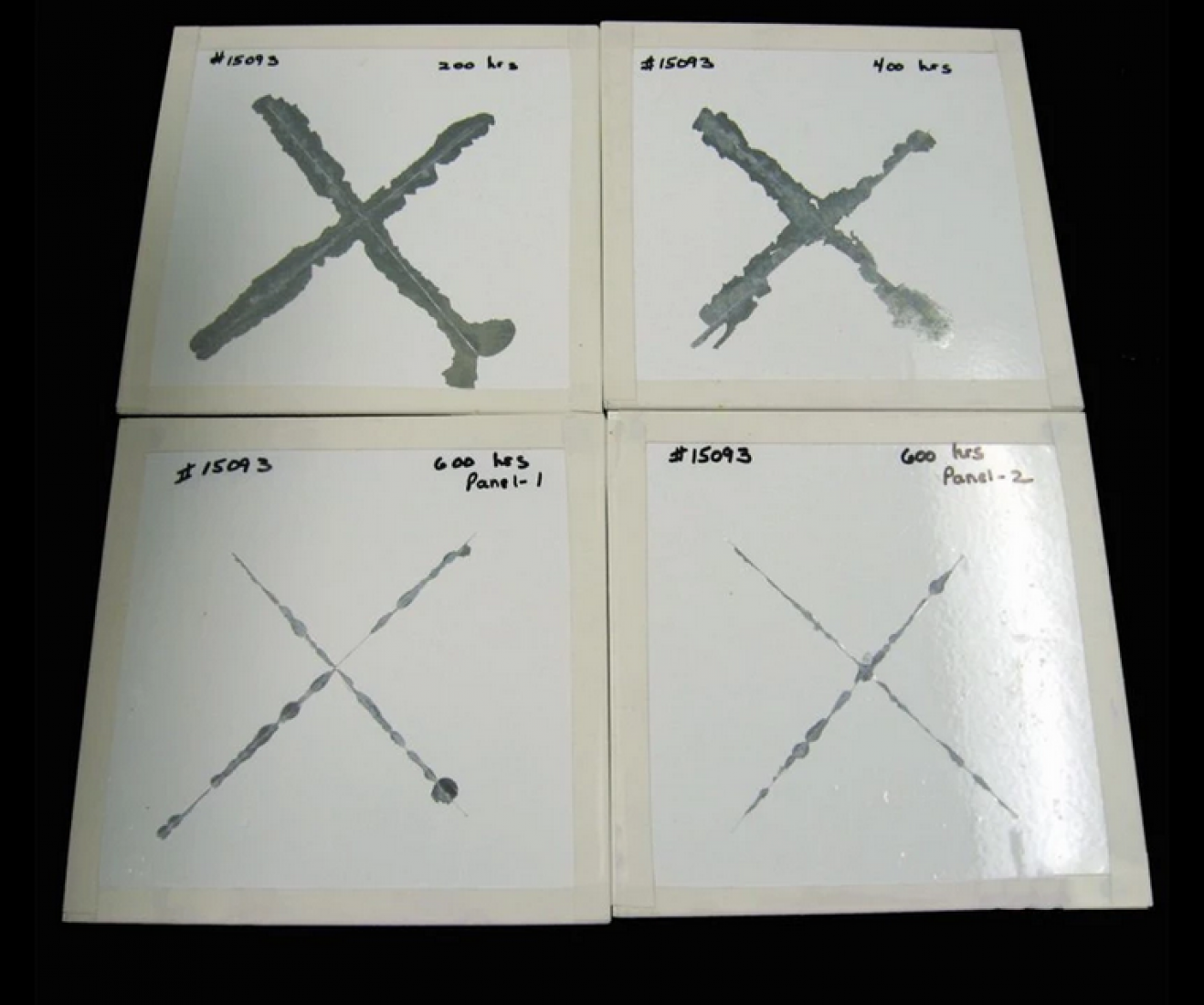

Applying thin zirconium-based conversional coatings (in nano-scale) over steel, aluminum or galvanized substrate leads to enhancement in performance parameters such as adhesion, corrosion resistance as well as increase in cathodic rupture of pigment.