Plasma is the fourth state of matter after solid, liquid, and gas states. However, this definition may be slightly confusing. More precisely, the plasma can be defined as a gas which is fully or partially ionized. According to this definition, plasma is a gaseous medium consisting of molecules, atoms, ions, and electrons. Due to the presence of charged particles, plasma has an electrical conductivity and is also strongly influenced by electric and magnetic fields.

Introduction

Plasma is the fourth state of matter after solid, liquid, and gas states. However, this definition may be slightly confusing. More precisely, the plasma can be defined as a gas which is fully or partially ionized. According to this definition, plasma is a gaseous medium consisting of molecules, atoms, ions, and electrons. Due to the presence of charged particles, plasma has an electrical conductivity and is also strongly influenced by electric and magnetic fields. It should be noted that the aforementioned definition is a general definition of plasma so even a gas which only 1% of its atoms are ionized can be considered as plasma. The density of plasma is determined by the degree of ionization; low density plasmas (e.g. ionization of only 1% of atoms) are typically called cold plasma.

As mentioned earlier, plasma is an electrical conductor, has discharge glow ability and is strongly affected by electromagnetic fields. Because of these characteristics use of this state of matter (usually cold plasma) has become commonplace in industrial and laboratory equipment. Typically, by applying a strong magnetic field, electric field or electric discharge in a gaseous medium, a gas like argon or helium can be ionized and generates plasma.

Plasma potentially has high-energy particles, so these particles can be accelerated in the presence of electric fields and hit the surfaces. Therefore, plasma can be used in textiles surface modification, etching and cleaning, polymerization, deposition and production of nanostructures. The collision of high-energy particles and their reaction with the surface of materials break the chains and lead to the formation of free radicals, while the properties of bulk materials remain constant.

Generally, the surface modifications by plasma can create or improve characteristics such as hydrophilicity, antistatic properties, capillary, chemical absorption, color absorption, printability, increasing the effective surface, creating active sites, adhesion and many other cases in produced textiles.

Application

Some applications of this device are as follows:

- Improving the color absorption and adhesion of surfaces

- Surface modification of fibers and polymers and altering their properties by changing the composition or structure.

- Enhancing the hydrophilicity, antistatic properties and improving the adhesion properties in fabrication of composite.

specification

Details of technical specifications are presented in the following Table.

Advantager of using nanotechnology

Advantager of using nanotechnology

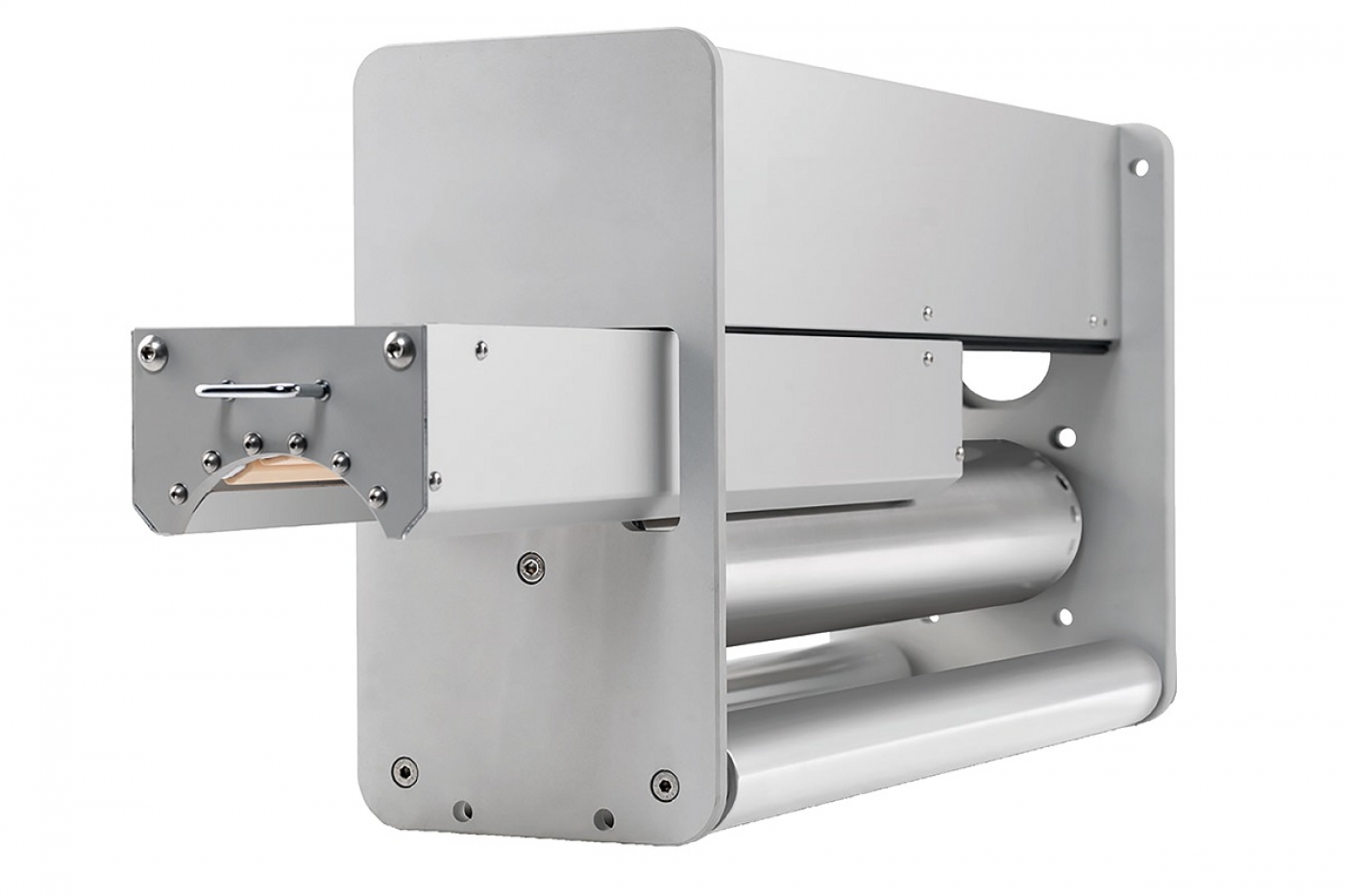

This device is designed and constructed with the aim of textiles surface modification, etching and cleaning, polymerization, deposition and production of nanostructures. Thus, utilizing this device can make nano scale surface modifications possible.

Manual and maintenance

For more details on how to use the device, refer to the device catalog and user guide.

Safety and package

- To improve user safety, use of ventilation system is recommended to discharge harmful gases into the outside atmosphere.