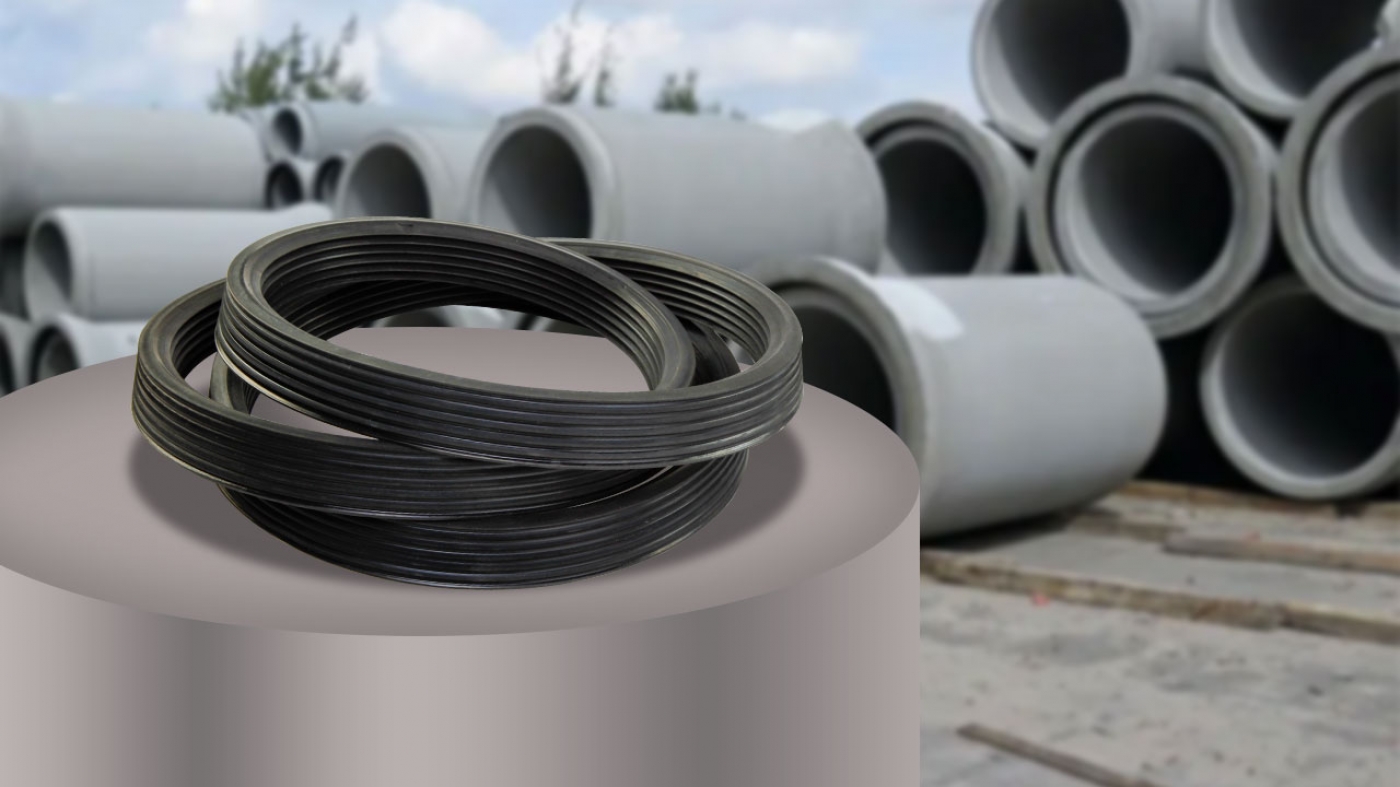

By using nanoparticles, the company has become able to increase the efficiency of joint sealing gaskets. Common joint sealing gaskets have lower efficiency than the ones produced by the company. Also, the longevity of these nanocomposite washers has been significantly increased and they have become economically affordable as well.

This company produces nanocomposite washers with improved properties by using silica nanoparticles. Continuous control and monitoring of water and sewage pipelines have considerable impact on quality of drinking water and waste water collecting process. All parts in pipelines are interconnected by various types of connections such as fixed, movable, flanged, threaded, and flexible connections. In order to prevent water leakage, polymer or rubber washers are used at joints of pipes. A gasket is a mechanical seal that is used to prevent leakage from the space between two pipes. The leakage could take place due to air or water pressure. Gaskets are usually produced through cutting sheets. Properties such as strength, elasticity and thermal as well as chemical stabilities are among the most important parameters in choosing a suitable washer. The company uses nanoparticles to produce washers and improve the mentioned properties.

Higher active surface of particles in elastomeric nanocomposites would be resulted in improved properties. Therefore, each part would have better appearance and also improved physical and mechanical properties. Meanwhile, high surface-to-volume ratio of nanoparticles provide high active surface. Also, a large number of nanoparticles are involved in structure indicating less swelling properties in different fluids.